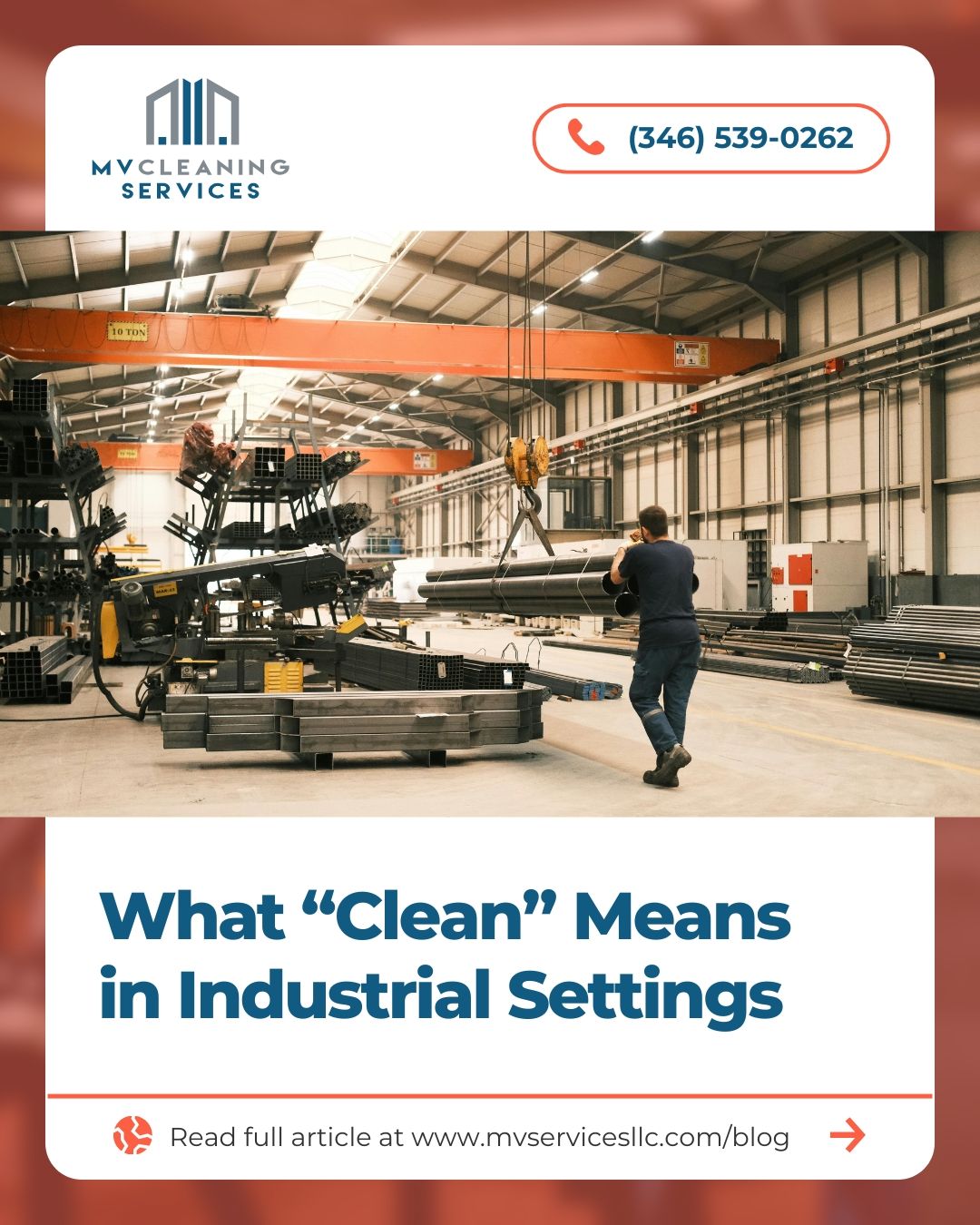

What “Clean” Means in Industrial Settings

Why Industrial Cleanliness is a Matter of Safety, Compliance, and Efficiency

In an office, "clean" might mean a spotless floor and a dust-free desk. In an industrial setting, be it a manufacturing plant, warehouse, or processing facility, the definition is vastly different and infinitely more critical. Here, cleanliness is not about aesthetics; it's a fundamental operational requirement that directly impacts safety, product quality, and the bottom line. It’s a disciplined process that goes far beyond a mop and bucket.

Understanding this distinction is key to running a safe, efficient, and compliant industrial operation.

-

Safety: The Non-Negotiable Priority

The number one reason for rigorous cleaning in industrial environments is safety. A clean floor is a safe floor, free from slip hazards caused by oil, water, or debris. But it goes deeper:

- Combustible Dust: In facilities working with wood, metal, grain, or chemicals, dust accumulation is not dirt—it's a explosive hazard. Regular, specialized removal is mandatory to prevent devastating fires or explosions.

- Clear Pathways: Keeping aisles, emergency exits, and around electrical panels clear of obstructions ensures safe evacuation and access for emergency personnel.

- Tool and Equipment Safety: Grease buildup on tools or machinery handles can lead to dangerous slips and accidents. Clean equipment is safer to operate.

-

Regulatory Compliance and Audits

Industrial facilities are governed by strict regulations from agencies like OSHA (Occupational Safety and Health Administration), the FDA (Food and Drug Administration), or EPA (Environmental Protection Agency). "Clean" in this context means passing a rigorous audit.

- Documentation: It’s not just about being clean; it’s about proving it with detailed cleaning logs, schedules, and safety data sheets (SDS) for all chemicals used.

- Cross-Contamination: In food processing or pharmaceutical manufacturing, cleaning protocols are designed to eliminate any risk of cross-contamination between batches or products, ensuring consumer safety.

-

Asset Protection and Preventive Maintenance

Industrial machinery is a massive capital investment. Grime, dust, and corrosive materials are its enemies.

- Performance: Dust clogging vents can cause motors to overheat and fail. Residual buildup can interfere with sensitive calibration.

- Longevity: Regular, proper cleaning of equipment is a form of preventive maintenance. It allows technicians to spot wear, leaks, or potential problems early, preventing costly downtime and extending the machinery's operational life.

-

Product Quality Control

In manufacturing, a single speck of dust or a microbe can ruin an entire product batch. Cleanliness is intrinsically linked to quality.

- Contamination Control: In settings like automotive painting, aerospace component assembly, or electronics manufacturing, cleanrooms with controlled particulate levels are essential. "Clean" here is measured in microns.

- Consistency: A standardized and meticulous cleaning process ensures that every product is made in the same controlled environment, guaranteeing consistent quality and reducing waste.

-

Operational Efficiency

A well-organized and clean facility is an efficient one.

- 5S Methodology: Many industries adopt the 5S system (Sort, Set in order, Shine, Standardize, Sustain), where "Shine" means cleaning and inspecting the workplace daily. This not only improves safety but also helps workers find tools and materials faster, reducing time spent searching and streamlining workflows.

Conclusion: Cleanliness as a Core Operation

In an industrial setting, cleaning is not a janitorial task, it is a technical, specialized, and critical operation. It requires trained personnel, specific equipment (like industrial vacuums rated for combustibles), and approved chemicals. It’s a strategic investment that mitigates risk, ensures compliance, protects assets, and upholds quality. For industry leaders, understanding this profound definition of "clean" is essential for success and sustainability.

Visit our BLOG for valuable insights and tips on our services and related topics. At MV Cleaning Services LLC, we regularly update our BLOG with new posts to keep you informed about the latest in commercial cleaning, healthcare sanitation, eco-friendly solutions, and more. Whether you manage an office, hospital, or industrial facility, you'll find useful information that can help you maintain a clean and healthy environment. Stay tuned for expert advice and updates on our comprehensive range of cleaning services.

MV Cleaning Services LLC, founded by Rogelio Velasco and Brenda Melgar, is a leading company in the commercial cleaning industry in Houston, TX, and surrounding areas, including Houston, The Woodlands, and Katy. With over eight years of experience, we offer a wide range of specialized cleaning services, including post-construction cleaning, move-in/move-out cleaning, commercial carpet maintenance, marble/stone restoration, floor care, window cleaning, deep cleaning, tile and grout cleaning, event cleaning, and upholstery cleaning.

Houston post construction clean up, commercial carpet cleaning, Houston move-in move-out cleaning, marble stone refurbishment, Houston wax polish floor care, window cleaning services, Houston deep cleaning experts, tile and grout cleaning, Houston event cleanup services, upholstery cleaning services, Houston commercial carpet care, professional marble refurbishment, Houston window cleaning services, detailed deep cleaning, Houston upholstery maintenance